Bill McDonough and Waste Management today announced a new partnership — the Waste Management-McDonough Sustainable Innovation Collaborative — aimed at advancing and improving recyclability and lessening the environmental impacts of products and packaging.

It’s a bold move on the part of America’s largest waste-hauling company, whose CEO, David Steiner, has long envisioned mining waste materials to create new value for Waste Management and its customers. The new collaborative aims to help producers, manufacturers, retailers and suppliers of packaged goods and products consider the recyclability as well as the ecological and human health impacts of materials, beginning with the design phase.

The catalyst for the partnership came barely a month ago, when McDonough and Steiner participated in a “sustainable solutions session” at Fortune Brainstorm Green, where participants explored the question, “How do we double America’s recycling rate in five years?” That session led McDonough and Steiner into a conversation about helping Waste Management’s manufacturing customers, especially consumer packaged goods companies, rethink their products and packaging from the perspective of their ultimate end-of-life disposition.

“David and I talked about the notion that it would be great if those at the end of the pipe could send signals back up the supply chain — that we could inform the whole system from the perspective of the people who are receiving complex and unrecyclable products,” McDonough told me.

The collaborative will serve primarily as a consultancy, something both Waste Management and McDonough — through McDonough Innovation, his design firm, as well as through McDonough Braungart Design Chemistry, which provides Cradle to Cradle consulting — are already doing. Waste Management, for its part, has people in manufacturing plants “managing the sustainability of manufacturing facilities and helping them with their strategies and tracking and metrics to make sure they are getting the right waste-diversion rates,” explains Chip Smith, Vice President of Marketing at Waste Management.

The two parties together stand to improve each other’s game. “We’re already doing some of this work today,” says Smith. “With Bill’s team, it brings a new piece of the puzzle — that is, the toxicity of packaging — that we don’t currently consult on today.” Smith explained that Waste Management’s focus has been principally on diverting waste from landfills, but not necessarily on the constituency of the materials it is keeping in circulation.

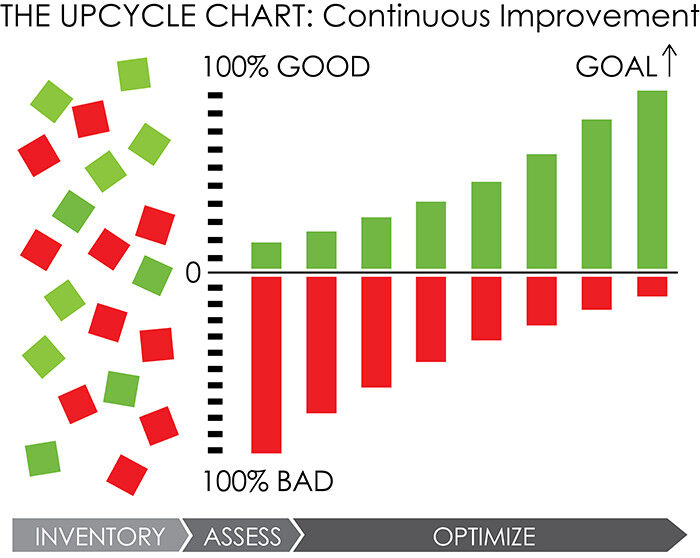

McDonough, the author of Cradle to Cradle: Remaking the Way We Make Things, and more recently, The Upcycle: Beyond Sustainability — Designing for Abundance, has for years taken the long, intergenerational view of waste: Why endlessly recycle products and packaging that contain ingredients that are toxic to human health and the natural environment? For McDonough, the emphasis on “zero waste” and similar efforts is misguided — it’s not the quantity of waste that’s important so much as the quality. If material quality is high, from an environmental and health perspective, there is unlimited potential for reuse in manufacturing systems, or to return the materials back to the soil as beneficial nutrients.

“Everything is food for something else,” he says. “Wouldn’t it be great if it was made healthy and reusable across generations? The opportunity here is to transform negative impacts into valuable assets. We can replace environmental liabilities with real value.”

For McDonough, one big opportunity is “access to the logistics.” He explained: “We can talk with companies about how they can be designing things that are safer, healthier and more optimal for recycling. But unless we have the systems in place to take advantage of that, it’s not as rich an opportunity as it can be. That’s what’s so elegant about this.”

The potential for the collaborative is to go beyond consultancy. McDonough believes there’s an opportunity to develop new design protocols and materials systems for customers. For example, “We can imagine putting codes on various kinds of materials that are coming at us, so that we know what they are and how to sort for them. Because we’re optimizing the logistics and reverse logistics, you can put these materials through their various use periods and you have a very rich opportunity to do design optimizations with people who would like to see the kinds of performance that this intelligence can bring into the next century.” Such efforts also stand to make Waste Management’s municipal waste facilities more efficient and profitable.

For now, both parties see a significant demand for consulting services. “We hear the upswell from customers saying they’re having to deal with more responsibility issues — they’re having to understand their products all the way through full life-cycle,” says Smith. “We’re hearing more and more of our customers look for solutions at the top of the funnel instead of the bottom of the funnel: How they can design products they know will be handled responsibly all the way through their end use?”

McDonough and Smith told me that some of the collaborative’s initial efforts will be focused at large companies to which both McDonough and Waste Management are already consulting independently, joining forces to deploy a more systemic approach to design, manufacturing and waste. They declined to name the companies in question.

Smith would only say, “We have some big things in mind.”